Description

Olympus Omniscan MX32-32 Ultrasonic Flaw Detector

Olympus Omniscan MX32-32 offers a high acquisition rate and powerful software features in a portable, modular mainframe to efficiently perform manual and automated inspections. With hundreds of units used throughout the world, the R/D Tech OmniScan MX is Olympus NDT’s most successful modular and portable phased array and eddy current array test unit. The OmniScan family includes the innovative phased array and eddy current array test units, as well as the eddy current and conventional ultrasound modules, all designed to meet the most demanding requirements of NDT.

Rugged, Portable, and Battery-Operated Olympus Omniscan MX32-32

The OmniScan is built to work in the harshest field conditions. Its solid polycarbonatebased casing and rubber bumpers make it a rugged instrument that can withstand drops and shocks.

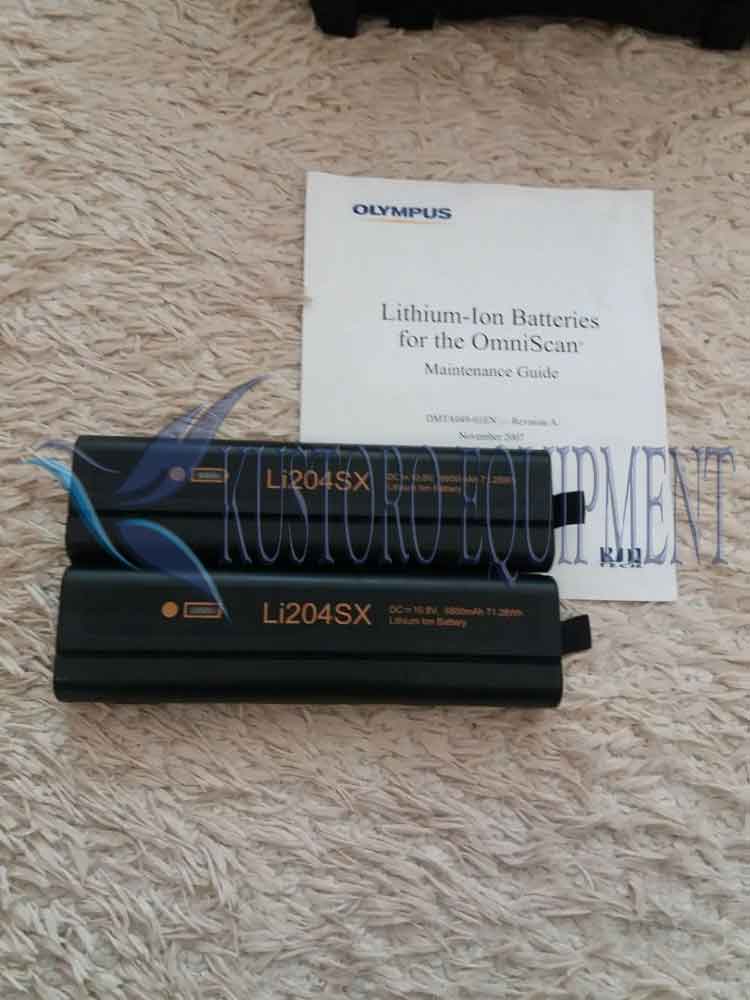

The OmniScan is so compact and lightweight (only 4.6 kg) that it can be carried easily and handled anywhere inside or outside. The OmniScan will run 6 hours with its two Li-ion batteries.

User Interface Olympus Omniscan MX32-32

The highly legible 8.4-inch real-time display (60-Hz A-scan refresh rate) with a SVGA resolution of 800 x 600 allows you to clearly see defects and details under any light conditions. A scroll knob and function keys make it easy to browse through and select functions. A mouse and a keyboard can also be plugged in for users looking for a more PC-like interface.

Modular Platform Olympus Omniscan MX32-32

The instrument is a modular platform that allows you to switch among its different test modules on location. The platform detects the new module and the technology supported so that the configuration and test environment are set automatically.

OmniScan Connector Olympus Omniscan MX32-32

The OmniScan connector has a probe ID feature that enables physical detection and recognition of the probe connected to the mainframe.

• Sets the probe to an appropriate frequency to prevent probe damage.

• Sets C-scan resolution of ECA probes.

• Loads the correct probe parameters.

Setup and Report Olympus Omniscan MX32-32

• Setup storage compatible with Microsoft Windows (exportable using a CompactFlash card)

• Complete report setup including reading configuration, which can be customized using HTML page layout

• On-screen interactive help that can be customized for procedure-oriented setups using HTML script templates

• Setup preview

• Predefined setups Connectivity, Data Storage, and Imaging The OmniScan offers alarm outputs as well as the standard PC ports: USB, SVGA out, and Ethernet. It offers internal data storage capability and extended storage via a CF (CompactFlash) card slot, as well as any USB or network storage.

Typical Applications Olympus Omniscan MX32-32

Girth Weld Inspection

Olympus NDT has developed a circumferential weld inspection system based on the OmniScan PA for the oil and gas industry. This phased array system is qualified to inspect tube with diameters ranging from 48 mm to 1524 mm and thicknesses from 5 mm to 25 mm in compliance with ASME Boiler and Pressure Vessel Code Section V. The semiautomated system offers better inspection speed and detection, and makes the interpretation of the indications significantly easier.

Pressure Vessel Weld Inspection

The combination of time-of-flight diffraction (TOFD) and pulse-echo techniques means that the complete inspection is done in a single scan, significantly reducing the inspection time when compared to conventional raster scanning or radiography. Inspection results are available instantaneously, allowing you to spot a problem with the welding equipment and fix it right away. Based on our vast experience in the nuclear and petrochemical industries, this system includes all the functions that are needed for code-compliant weld inspections.

Aircraft Fuselage Inspection

The OmniScan ECA (eddy current array) provides the ability to detect hidden corrosion and cracks in multilayer structures. Currently, material loss of 10% of the lap splice thickness can be detected in aluminum at a depth of 0.2 in. Surface and subsurface cracks can be detected in the skin, at the fastener, or at the lap joint edges.

Ultrasound Inspection

Time-of-Flight Diffraction (TOFD) Testing TOFD is a technique that uses two probes in pitch-and-catch mode. TOFD detects and records signals diffracted from defect tips for both detection and sizing. The TOFD data is displayed in a grayscale B-scan view. TOFD offers wide coverage and amplitudeindependent sizing compliant with the ASME-2235 code.

• One-line scan for full-volume inspection

• Setup independent of weld configuration

• Very sensitive to all kinds of defects and unaffected by defect orientation

Time-of-Flight Diffraction (TOFD) and Pulse-Echo Testing While TOFD is a very powerful and efficient technique, it suffers from limited coverage resulting from two dead inspection zones: one dead zone is near the surface, the other is at the backwall.

OmniScan UT allows inspections simultaneously combining TOFD with conventional pulse echo. Pulse echo complements TOFD and covers the dead zones.

• TOFD inspection

• 45° pulse-echo for weld cap inspection on either sides of the weld

• 60° pulse-echo for weld root inspection on either sides of the weld

0-Degree Testing (Corrosion and Composite)

The 0-degree testing measures time-offlight and amplitude of ultrasonic echoes reflecting from the part into gates in order to detect and measure defects.

• C-scan imaging

• Full A-scan recording with C-scan postprocessing

Ultrasound Transducers

Olympus NDT offers thousands of transducers in standard frequencies, element diameters, and connector styles.

• Contact and immersion transducers

• Dual transducers

• Angle beam transducers and wedges

• Replaceable delay line transducers

• Protected-face transducers

• Normal incidence shear wave transducer

Ultrasound Software Olympus Omniscan MX32-32

Full-Featured C-Scan

• Monitors amplitude, peak position, crossing level position, and thickness on each gate

• Automatic gate synchronizes from previous gate for higher dynamic range of thickness.

• A-scan data storage and C-scan postprocessing capabilities

• Optional IF gate for surface following synchronization or measurement gate or TCG/DAC curves

• Either positive or negative gate on RF signal (independent for each gate)

• Eight alarms completely configurable on single gate events or multiple gate events, filter for n occurrences from one or multiple channels

• Customizable color palette for amplitude and thickness C-scan

• Adjustable 256-level color palette

• 2-axis mechanical encoder with data acquisition synchronization on mechanical movement

• Optional data library to access A-scan and/or C-scan on PC for custom processing

Full-Featured B-Scan

• Easy-to-interpret cross-sectional view of inspected part

• Excellent display of corrosion mapping of boilers, pipes, and storage tanks

• Visual identification of the thickness values acquired

• Encoded TOFD capability for amplitude-independant defect sizing

Full-Featured A-Scan

• Color-selectable A-scan display

• Reject mode

• Hollow mode

• Peak-hold mode (always keeps the signal that shows the maximum amplitude in gate A)

• Gate threshold level crossing (changes the color of the curve that is over the gate level)

• 60 Hz A-scan refresh rate with overlays of envelope and peak inside the gate

Step-by-Step calibration Wizards Olympus Omniscan MX32-32

All calibration procedures are guided using step-by-step wizards.

• Sound velocity calibration

• Wedge delay calibration

• TOFD calibration

• TCG calibration

• Encoder calibration

TOFD Option

• B-scan encoded data imaging and storage

• Adjustable for brightness and contrast grayscale color palette

• 100 MHz A-scan digitizing

• TOFD calibration wizard online and offline

• Hyperbolic cursor and reading for TOFD sizing

• Lateral wave resynchronization

Specifications Olympus Omniscan MX32-32

| Overall dimensions (W x H x D) | 325 mm x 235 mm x 130 mm (12.8 in. x 9.3 in. x 5.1 in.) |

| Weight | 3.2 kg (7 lb), no module and one battery |

Data Storage |

|

| Storage devices | SDHC card, most standard USB storage devices, or fast Ethernet |

| Data file size | 300 MB |

I/O Ports |

|

| USB ports | 3 |

| Speaker out | Yes |

| Video output | Video out (SVGA) |

| Ethernet | 10/100 Mbps |

I/O Lines |

|

| Encoder | 2-axis encoder line (quadrature, up, down, or clock/ direction) |

| Digital input | 4 digital TTL inputs, 5 V |

| Digital output | 4 digital TTL outputs, 5 V, 15 mA |

| Acquisition on/off switch | Remote acquisition enabled TTL, 5 V |

| Power output line | 5 V, 500 mA power output line (short-circuit protected) |

| Alarms | 3 TTL, 5 V, 15 mA |

| Analog output | 2 analog outputs (12 bits) ±5 V in 10 kΩ |

| Pace input | 5 V TTL pace input |

Display Olympus Omniscan MX32-32 |

|

| Display size | 26.4 cm (10.4 in.) (diagonal) |

| Resolution | 800 pixels x 600 pixels |

| Brightness | 700 cd/m2 |

| Number of colors | 16 million |

| Type | TFT LCD |

Power Supply Olympus Omniscan MX32-32 |

|

| Battery type | Smart Li-ion battery |

| Battery life | Minimum 7 hours with two batteries |

Environmental Specifications |

|

| Operating temperature range | -10 °C to 45 °C (14 ºF to 113 ºF) |

| Storage temperature range | –20 °C to 60 °C (–4 ºF to 140 ºF) with batteries –20 °C to 70 °C (–4 ºF to 158 ºF) without batteries |

| Relative humidity | Max. 70% RH at 45°C noncondensing |

| Ingress Protection Rating | IP54 |

| Shockproof rating | Drop-tested according to MIL-STD-810G 516.6 |

Phased Array Module Specifications (Applies to OMNI-M-PA3232) |

|

| Voltage | Low: 50 V Medium: 100 V High: 200 V |

| Pulse width | Adjustable from 30 ns to 500 ns; resolution of 2.5ns |

| Fall time | <5 ns |

| Pulse shape | Negative square pluse |

| Output impedance | <30 ohms |

Receiver |

|

| Gain range | 0 dB to 74 dB in steps of 0.1 dB, maximum input signal 1.1 vP-p |

| Input impedance | 50 Ohms |

| System bandwitdth | 0.53 MHz to 23 MHz + 10% (-3 dB) |

Beam formation |

|

| Scan type | Sectorial and linear |

| Aperture | 32 elements |

| Numbe of elements | 32 elements |

| Number of focal laws | 256 |

| Delay range transmission | 0 us to 10 us in 2.5 ns increments |

| Delay range recetption | 0 us to 10 us in 2.5 ns increments |

Acquisition Specifications |

|

| Frequency | |

| Digitizing frequency | 100 MHz (10 Bits) |

| A-scan (acquisition mode) | Up to 6000 A-scans per second (512-point, 8-bit A-scan) |

| Maximum pulsing rate | Up to 10 KHz (C-scan) |

| Depth in material | 59.8 meter in steel (longitudinal wave), 10 ms in with compression 0.49 meter in steel (longitudinal wave), 81.9 us without compression |

Display Olympus Omniscan MX32-32 |

|

| Refresh rate | A-scan: 60 Hz; s_scan: 20 Hz to 30 Hz |

| Envelope (echo-dynamic mode) | Yes: Volume-corrected S-scan (30 Hz) |

Synchronization Olympus Omniscan MX32-32 |

|

| On internal clock | 1 Hz to 10 kHz |

| External pace | Yes |

| On encoder | on Axes: from 1 step to 65536 steps |

Data Specifications Olympus Omniscan MX32-32 |

|

| Number of data points | Up to 8000 |

| Real-time averaging | 2, 4, 8, and 16 |

| Rectification | RF, full wave, half wave+, half wave- |

| Filtering | Low-pass (adjusted to probe frequency), digital filtering (bandwidth, frequency range) |

| Video filtering | Smoothing (adjusted to the probe frequency range) |

Programmable TCG |

|

| Number of points | 16: one TCG(time-corrected gain) curve per channel for focal laws |

Storage Olympus Omniscan MX32-32 |

|

| A-scan recording | 6000 A-scans per second (512-point, 8-bit A-scan) |

| C-scan recording | I, A, B, up to 10 kHz |

| Maximum file size | Limited to available internal flash memory; OmniScan MX2: 300MB |

Package Includes :

- Olympus OmniScan MX2 32:32 Phased Array Flaw Detector

- Battery Pack

- AC Adapter/Charger

- Power Cord

- User Manual On Cd-ROM

- Carrying Case (G)

Additional information

| Lead Time | 5-7 days |

|---|---|

| Packaging | Box |

Reviews

There are no reviews yet.